- Products

- Service

- Expertise

- References

- fischer group

| ETA-approval | |

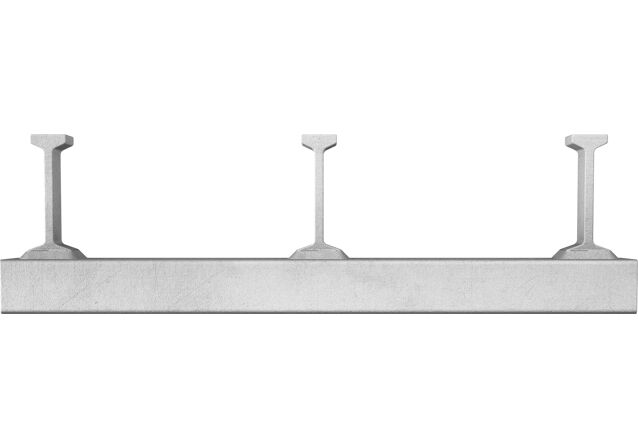

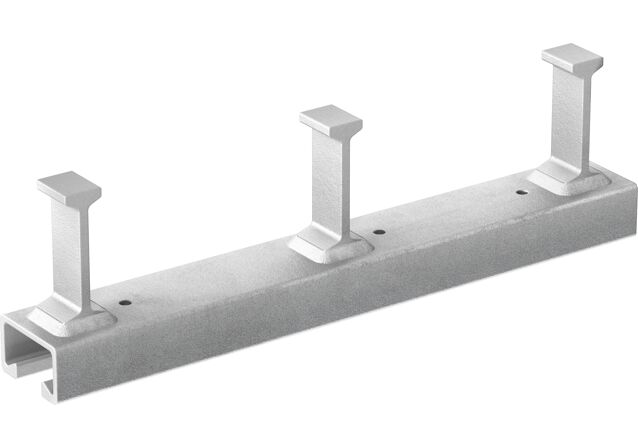

| Profile | 50/30 |

| Length ( l ) | 6.070 mm |

| Number of anchors | 25 |

| Serrated | No |

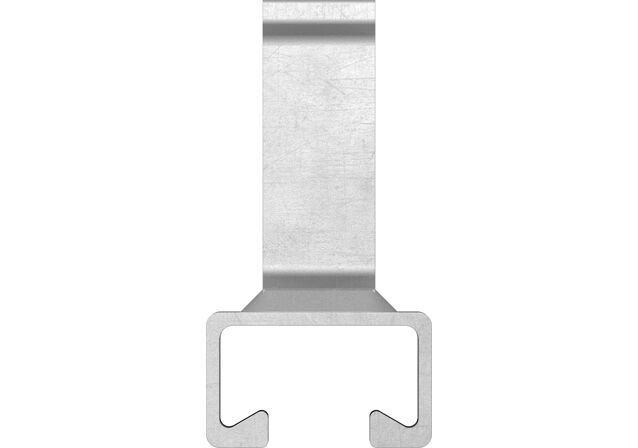

| Type | I-Anchor |

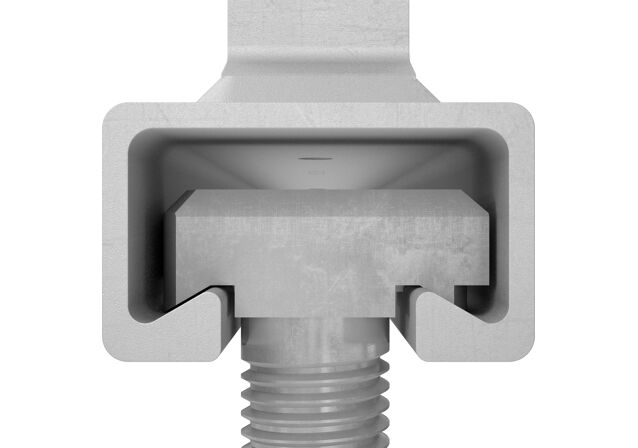

| Match | FBC-50/30 / FBC-N-50/30 |

| Thread ( M ) | M10 - M20 for FBC-50/30 or M16 - M20 for FBC-N-50/30 |

| Amount | 1 pcs. |

| GTIN (EAN-Code) | 4048962359992 |